Optimization of a hydrogen-burner for on-board LOHC dehydrogenation

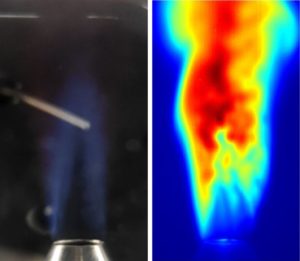

Hydrogenflame of the single nozzle burner, on the right: recording with infrared camera

In this project, a scalable, modular and low-emission hydrogen burner for the dehydrogenation of LOHCs (Liquid Organic Hydrogen Carriers) is developed. The concept is based on a matrix burner whose scalability is realized by expanding the number of nozzles. A partially premixed single nozzle burner was first designed, tested and optimized. Experimental studies show stable operation for various burner configurations over a wide load range. Lean burner operation and combustion air humidification can reduce NOx emissions to < 10 ppmv. The further development to a matrix burner is taking place in two steps. First, a single-row burner is developed for which the uniform distribution of combustion air and hydrogen to the nozzles is investigated. Second, the single-row burner is expanded into a matrix burner by increasing the number of rows. Switching individual nozzle rows on and off enables an operation over a wide load range with the same burning behavior.

This work was funded by the Bavarian Ministry of Economic Affairs, Regional Development and Energy through the Helmholtz-Institute Erlangen-Nürnberg for Renewable Energy (HI ERN) and is part of the project “Emission-free and highly emission-reduced rail traffic on non-electrified lines”.